New 2024 catalogues

Need a measuring instrument? We’re sure to have what you’re looking for: testers, Voltage Absence Testers, multimeters, oscilloscopes, power loggers, etc.

Need a measuring instrument? We’re sure to have what you’re looking for: testers, Voltage Absence Testers, multimeters, oscilloscopes, power loggers, etc.

Check out our catalogues.

Catalogues in English:

> CHAUVIN ARNOUX-METRIX Catalogue

> Multimetrix Catalogue

Simple instruments to help you understand electrochemistry!

CA 10101E communicating pH-meter

Compatible with the REGRESSI software, the CA 10101E pH-meter is ideal for the measures needed for acid-base titration of a solution.

The Rearview Mirror - Advertising

The evolution of Pyrocontrole's advertising has been a fascinating process, following the trends in marketing and communication over the years. Pyrocontrole Chauvin Arnoux Group, specialized in manufacturing temperature control systems, has adapted its advertising strategy to reach ever-wider audiences, taking on board the technological changes.

1// Pyrocontrole

The evolution of Pyrocontrole's advertising has been a fascinating process, following the trends in marketing and communication over the years. Pyrocontrole Chauvin Arnoux Group, specialized in manufacturing temperature control systems, has adapted its advertising strategy to reach ever-wider audiences, taking on board the technological changes.

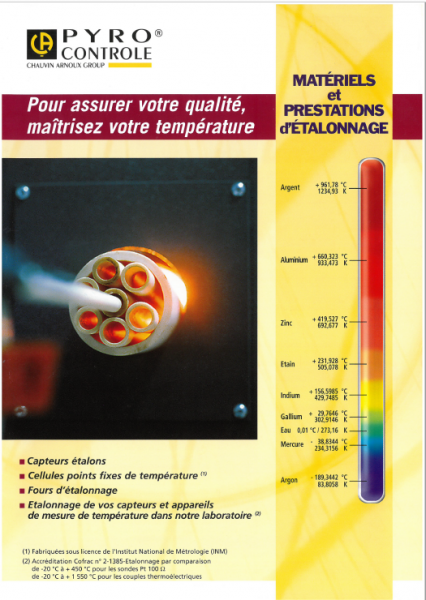

At first, in the 1960s, traditional advertising methods were the focus: adverts in specialized magazines, printed brochures and posters to promote the advantages of its temperature control systems.

With the arrival of the Internet and the rise of digital marketing, Pyrocontrole quickly understood the importance of being present online. The company thus developed a professional website in the 2000s, offering a virtual shop window to present our products and provide information to customers. This digital turn also led Pyrocontrole to explore online advertising. Targeted advertising banners and contextual ads were used to reach professionals in industry via various digital channels.

Today, with the explosion of social media, their advertising strategy has moved towards these increasingly popular platforms. The creation of profiles on social media such as LinkedIn and Twitter has allowed direct interaction with the customer and made it possible to share relevant content: case studies, customer testimonies, specialized articles, etc. Shared content which reinforces the company's legitimacy and shows how to use the products, probes and temperature controllers in their various industrial applications. Social media also help to promote our products more visually by sharing pictures and training videos.

As it seeks constantly to innovate, Pyrocontrole has now integrated influence-based marketing into its communication strategy. By working with renowned experts in the field of temperature and industrial control, we benefit from their credibility and influence to promote out products among a targeted audience. These strategic partnerships raise Pyrocontrole's profile and position us as experts in our sector of activity.

Advertising at Pyrocontrole has evolved dynamically, shifting from traditional methods to digital and online strategies. Using websites, online advertising campaigns, displays, social media content and strategic partnerships, Pyrocontrole has succeeded in adapting to the new trends in communication and reaching a broader audience.

2// Graphical evolution

Since advertising's earliest days, the graphical appearance of the ads has changed significantly. The first advertisements were simple and text-based, whereas modern adverts have become much more complex and graphics-driven. This graphical evolution has been influenced by the changes in image production techniques, consumer expectations and technological advances.

Initially, the adverts often comprised a text and a slogan. Pictures were rare and usually limited to simple illustrations or engravings. These adverts were often intended to be read rather than seen. Newspapers and magazines were the main advertising media and the cost of colour printing was prohibitive, so most ads were in black and white.

In the 1950s and 1960s, adverts became even more elaborate, with the use of photos and more creative page layouts. Advertisements began to use bright colours and striking pictures to attract consumers' attention. Advertisers also started using psychological principles to create more effective adverts, using pictures and colours to play on consumers' emotions.

In the 1980s and 1990s, advertisements became even more sophisticated, with the use of information technology to create digital images and animations. TV advertising became more widespread and was used to create more visual advertisements. Magazine advertising has also evolved, with larger, brighter colour pictures.

Currently, advertisements have reached an unprecedented level of sophistication. Advertisers use advanced image production techniques to create very elaborate, visually striking ads. Online adverts have evolved too, with interactive ads allowing consumers to interact with brands and products. The ads are also more closely targeted and customized; using behavioural data and algorithms to create adverts which are more relevant for consumers.

To sum up, the graphical evolution of advertising reflects the progress made in technology and image production, as well as changing consumer expectations. Modern advertising is much more sophisticated, more visual and more targeted than ever before and continues to develop.

3// Did you know?

The origin of advertising lies in Antiquity, when traders used shop signs to mark their presence and attract customers. However, modern advertising as we now know it started to take form in the 19th century with the explosion of the print media. Advertisers began using advertising space in newspapers to promote their products and services. Over time, advertising spread to new media, such as the radio, TV and Internet, and evolved to include sophisticated marketing techniques such as targeted advertising and marketing influencers. Advertising has become an essential feature of modern life, shaping our perceptions and our consumption choices.

Check out our 2024 Selected Products Catalog!

From relays to power monitors, as well as our current transformers, check out all our company's know-how for your needs. This document contains 20 pages of concentrated technical information, proposing expertise and products for each of your issues.

In this new edition, come and see our new products, the Ulys MD45-M EV and ULYS TD100-M EV, both intended for electric vehicle charging applications, and our new solution for monitoring low-voltage installations: Gridwatch!

New service from Manumesure: noise exposure measurement / sound dosimetry on operators

In the context of the prevention of risks linked to employees' exposure to noise, Manumesure helps companies to perform noise measurements at the workstation. Workers' noise exposure is determined using dosimeters placed on the people exposed. The values measured in dB(A) and dB(C) are compared with the limit values defined in Article R4431-2 of the French Labour Code. Sound dosimetry can also be used to check whether workers are sufficiently protected in terms of Individual Noise Protection: headphones, disposable and moulded ear plugs, etc.

Manumesure's teams work on site to assess and measure the noise levels to which workers are exposed by using dosimeters.

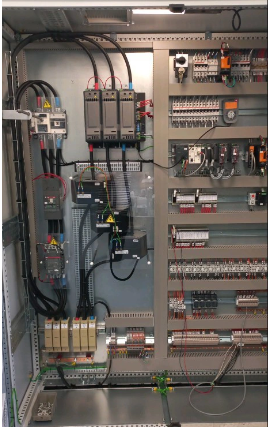

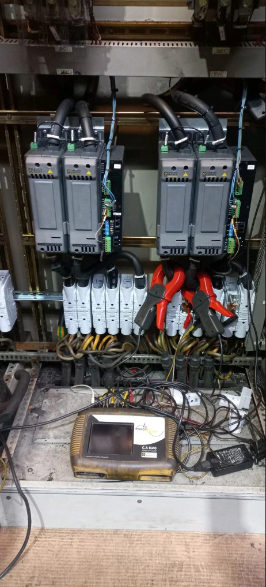

At the heart of our products – Implementation of Thyritop 600 at an automotive group

Today, iour temperature control experts are optimizing the performance settings of the Thyritop 600 as part of the modernization of a crankcase curing oven.

The temperature controllers from the Thyritop 600 series are installed in a gigantic oven. With a length of over 25 meters and spanning two floors, this oven is the beating heart of the automotive production site. Integrated into this industrial thermal process, our Thyritop controllers will optimize the operational and energy efficiency of the manufacturing ovens for blank parts, including those made of nodular cast iron and aluminum alloy (powertrain and chassis components). These parts will then be sent to the machining and/or assembly units and bodywork paint curing tunnels.

However, optimizing their installation requires manufacturer expertise and meticulous parameterization to meet the required quality standards. The challenge for Pyrocontrole and our partner lies in retrofitting this oven through an essential upgrade to achieve the ambitious goals set: producing up to 3.5 million crankcases per year. To accomplish this, the intervention of our experts is crucial. Their product knowledge and parameterization expertise are key to ensuring that production is efficient, safe, and responsible in terms of energy consumption.

.

The benefits of this collaboration are not limited to this installation. Indeed, its impacts are tangible on several levels. The controllers implemented will not only optimize the operational efficiency of the ovens but also enhance their energy performance. This represents a significant improvement in a context where sustainability has become an industrial imperative.

More technical information...

Products // Thyritop 600 3Ph and 2Ph power controller at 100A, 150A, 200A, and 400A

Voltage // 400V for 100A, 150A, and 200A, 690V for 400A

Loads // Star-connected resistances without neutral

Conduction mode // Wave train

Options // HB - partial and total load break detection + UIP - power control UxI, U², I², U, I

Fieldbus // Profinet

Did you know?

In industry, the term "retrofit" generally refers to the process of modernizing or upgrading existing equipment, systems, or facilities to make them more efficient, more effective, or compliant with new standards or requirements.

Retrofitting may involve various actions, such as installing newer components or technologies, upgrading software, improving energy efficiency, or even completely reconfiguring systems to meet new needs or goals.

This process is often used in sectors such as manufacturing, engineering, energy, aerospace, and others where existing equipment needs to be kept relevant and competitive in an ever-changing environment. Retrofitting can help businesses to extend the useful life of their existing investments while leveraging the latest technological advances, which may be more cost-effective than completely replacing equipment.

How to control Data Centers' electricity consumption with our Ulys meters

Data centers, those pillars of the world's digital infrastructure, are essential for our day-to-day life online. However, there is considerable energy consumption behind every click and query. According to data provided by the International Energy Agency (IEA), data centers consumed nearly 200 terawatt hours (TWh) of electricity in 2020, accounting for about 1% of worldwide electricity demand. This energy footprint continues to grow and is expected to increase three to tenfold by 2030 according to various estimates. This trend raises questions concerning the environmental impact of digital infrastructure, encouraging us to rethink our approach to energy management in data centers.

To monitor consumption and thus identify any sources of potential savings, the multi-channel Ulys MCM meter is the ideal solution.

The Ulys MCM offers concentrated innovations: its small size and its easy-to-install accessories make it simple to integrate in your electrical cabinets for retrofitting or new projects.

One unusual feature of data centers is that they are equipped with a very large number of low-power electrical feeders: a perfect match for the Ulys MCM which can measure multiple electrical feeders (up to 18 three-phase feeders or 54 single-phase feeders) with just one meter!

Some data centers are called "co-rental data centers", which means that a single data center may house servers and other equipment from numerous customer companies. In this case, the energy is billed by one actor to another, so the electricity meters used must comply with the European MID directive. This is the case for our two meters: Ulys MD45-M Modbus for monitoring single-phase feeders and the Ulys TD80-M Modbus for metering on three-phase feeders.

These are communicating, interoperable products which are easy to integrate into a metering plan or any other kind of energy supervision.

The challenges and solutions for reducing data centers' energy consumption while maintaining the effectiveness and reliability needed in our interconnected world remain a major issue for the future. Chauvin Arnoux Energy is working actively to provide solutions to such problems!

Manumesure is helping to draft the French standard for PFAS sampling and analysis

On April 5th, 2024, the French government published an interministerial action plan requiring in particular better knowledge of the atmospheric emissions linked to PFAS (per- and polyfluoroalkyl substances).

The technical rules to be followed for PFAS sampling in Installations classified for environmental protection (PCIs) were defined by the note dated March 7th, 2024, published by the Direction Générale de la Prévention des Risques (DGPR - Directorate General for Risk Prevention).

MANUMESURE is actively participating in the AFNOR meetings and is helping to draft the French standard for PFAS sampling and analysis.

If you want to check on PFAS in your atmospheric emissions, please contact MANUMESURE.

For info (in French):

The ministerial PFAS plan:https://lnkd.in/dmhyF9yE

Note by the DGPR:https://lnkd.in/d9AQXFNR

Learn all about installing your Ulys Flex meter!

Installing an electricity meter on current transformers is difficult and costly on high-powered electrical feeders and is sometimes even impossible for feeders which are difficult to access.

Thanks to its compact, flexible current sensors with a very wide dynamic range, ULYS FLEX is the ideal solution for these applications.

Intended for energy metering and management applications, the ULYS FLEX submeter can be used both locally, with its 3-line backlit screen, and remotely via its integrated communication capabilities.

Don't worry about commissioning your Ulys Flex: our new FAQs will help you!

ATEX certification renewed!

Renewal of ATEX certification for Pyrocontrole's range of ambient sensors

ATEX is a European directive certifying that a product complies with the technical stipulations concerning zones subject to explosive atmospheres and the associated risks.

Drawing on its expertise in the chemicals, nuclear and hydrogen sectors, Pyrocontrole proposes a complete set of pyrometer assemblies developed specifically for these cutting-edge industries with harsh constraints and hazardous environments.

Whether for standard equipment or tailored products, our R&D teams can handle any industrial complexity.

Pyrocontrole keeps a close eye on the quality and standardized design requirements of its equipment, as well as on user safety.

The sensors are available in explosion-proof versions (Ex d protection mode ) and intrinsic safety versions (Ex i protection mode) for gas and dust zones (categories 1,2,3 G/D).

Our teams design and develop measuring instruments for this sector, according to the applications and regulatory stipulations: European ATEX directive and the PED pressurized equipment directive.

Reduction of your maintenance costs and energy spending while decarbonizing; Pyrocontrole's temperature sensors offer multiple advantages.

To learn more, see our Temperature Sensors product catalogue.