Low-Voltage Directive

If the safety test report and EMC test report are satisfactory, they enable approval of the CE label on the device

There are 2 parts to the LVD: EMC and electrical safety

Electrical safety is covered by directive 2006/95/CE issued by the European Parliament and the Council on 12th December 2006. It concerns electrical devices intended for use in the following voltage conditions:

-

-

- between 50 V and 1,000 V for alternating current

- between 75 V and 1,500 V for direct current

-

Applicable standards:

- NF EN 61010-1. Concerns electrical measuring, control and laboratory devices. General requirements.

- NF EN 61010-2-030. Specific requirements for test and measurement circuits.

- IEC 61010-031. Safety instructions for equipped handheld probes for electrical measurements and tests.

- IEC 61010-2-032. Specific requirements for portable and handheld current sensors for electrical tests and measurements.

- IEC 61010-2-033. Specific requirements for portable multimeters and other measuring devices for domestic and professional use which are capable of measuring the network voltage.

The safety assessment of a device is performed jointly by several people (engineering teams) while taking into account the data concerning the design of the device. In short, the safety test report is a summary of a device's design.

EMC

Qualify the Electromagnetic Compatibility of your equipment

Manumesure has an Electromagnetic Compatibility (EMC) test laboratory at its technical centre in Pont-L’Evêque (France).

The Chauvin Arnoux Group's measuring instruments and equipment are all qualified in this laboratory.

This laboratory is also available for industrial companies seeking to qualify the electromagnetic compatilibility of their equipment with regard to the EMC regulations.

Please do not hesitate to contact us.

EMC, CE marking and the European Directive

Electromagnetic compatibility (abbreviation: EMC) is the capability of a device or system to operate satisfactorily in an electromagnetic environment, without causing intolerable electromagnetic disturbances for everything else in the environment.

European Directive 2004/108/CE replacing Directive 89/336/CE makes EMC tests mandatory for all electrical and electronic devices. It obliges industrial companies to place CE marking on all such products, thus proving that they comply with the EMC standards applicable to them (among other aspects).

Immunity tests

According to the NF EN 61000-4-2 ... 4-11 standards

61000-4-2: Electrostatic discharges: contact discharge 8 kV - air discharge 15 kV

61000-4-3: Radiated immunity:

-

-

-

-

- 3 V/m at 3 metres between 80 MHz and 2.7 GHz

- 10 V/m at 3 metres between 80 MHz et 2.5 GHz

-

-

-

61000-4-4: Fast transients and bursts:

-

-

-

-

- 4 kV with direct injection on single-phase and three-phase coupler

- 4 kV by coupling clamp

-

-

-

61000-4-5: 1.2/50 µs shock waves: 4 kV by single-phase coupler

61000-4-6: Conducted radio-frequencies: 3 V and 10 V between 150 kHz and 80 MHz with CDNs (coupling-decoupling networks) and injection clamp

61000-4-8: Magnetic field: 100 A/m in Helmholtz coils

61000-4-11: Short interruptions and voltage dips: single-phase test

Susceptibility tests

According to the NF EN 55011 standard

Radiated emissions: from 30 MHz to 1 GHz at 3 metres. Automated turntable and antenna for in-depth determination of the maximum values

Conducted emissions: measurement with single-phase LISN from 150 kHz to 30 MHz

Water quality

Water quality sampling and analysis

Analyses according to specifications

MANUMESURE can test the quality of waste water, rain water and underground water on any site.

Various parameters can be measured according to the customer's specifications: pH, temperature, chemical oxygen demand, pesticides, BOD5, suspended solids, PCBs, total hydrocarbons, heavy metals, nitrates, etc.

Waste water and rain water quality tests

Sampling and methodology

Sampling is performed in compliance with the ISO 5667 standards on water sampling and the FD T 90-523-2 document: "Water Quality - Sampling guide for monitoring water quality in the environment - Waste water sampling".

Two types of sampling are possible: 24-hour survey or point sampling.

24-hour survey

Sampling using a flow-controlled or time-controlled sampling system with continuous measurement of pH and temperature. When sampling has finished, an average sample representative of the day when measurement took place is established and analysed.

This sampling method allows assessment of the average daily values for waste water.

Point sampling

This method, used to assess the instantaneous value for an effluent, is used for effluent which remains homogeneous over time or for effluent linked o a specific event: rain, accidental pollution, etc.

Types of analyses

Various parameters can be measured according to the customer's specifications: pH, temperature, chemical oxygen demand, pesticides, BOD5, suspended solids, PCBs, total hydrocarbons, heavy metals, nitrates, etc.

Monitoring of underground water quality

This sampling and analysis has two main aims:

- Checking that water quality has not been altered by agricultural, industrial or other activities.

- Detecting any pollution or monitoring the evolution of a pollution event already detected.

Methodology

These measurements are performed in compliance with AFNOR technical document FD X31-615 "Soil quality - Methods for detecting and characterizing pollution - Sampling of underground water in a bore-hole".

Our technical resources enable us to take samples at depths of up to 70 metres.

Types of analyses

Various parameters can be measured according to the customer's specifications: pH, temperature, chemical oxygen demand, pesticides, BOD5, suspended solids, PCBs, total hydrocarbons, heavy metals, nitrates, etc.

Measurement report

At the end of the measurement campaign, a report is drawn up presenting the methodology, a site description, the analysis results and a comparison with the regulated values.

Noise measurement

Noise-level measurements on the property lines of industrial sites

Manumesure performs regulatory noise-level tests on installations classified as environmentally sensitive.

These measurements are intended to check the noise levels on the property lines of industrial sites (excluding buildings) and in regulated noise emergence areas.

Two French decrees (dated 20/08/85 and 23/01/97) provide the reference in terms of regulations.

Methodology

The measurements are performed with Class-1 sound-level meters, in compliance with the NF S 31-010 standard concerning “Characterization and measurement of environmental noise”.

- Acquisition of the noise levels is performed during a period representative of the company's normal operations (minimum 30 minutes) and requires suitable climatic conditions (no heavy rain or high winds).

- The admissible noise levels on the site's property lines are tested at the locations specified by the regulations. If this is not possible, the measurement locations are determined according to the respective positions of the installation and the regulated noise emergence areas, so that the potential effect of the installation's noise emissions on inhabited areas can be assessed representatively.

Report

At the end of the measurement campaign, a report will be drawn up presenting the methodology, the measurement results (admissible levels on property lines, noise emergence, noticeable tones) and compliance with the regulations.

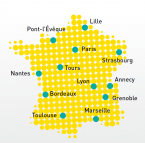

Quick response all over France

With its network of technical centres covering the whole of France, Manumesure is capable of responding quickly to any requests.

Each centre includes technicians qualified for noise measurements and high-performance equipment.

Air quality measurement

25 years of expertise in air quality analysis

Watch the video (in French)

Accreditations & approval

Manumesure has COFRAC Tests accreditation,

according to the “Air quality, Fixed-source emissions -

LAB REF 22“ reference document and according to the QAL2 and AST procedures.

• Pont-l’Evêque (France) - COFRAC Tests accreditation

no. 1-1318

• Lyon / Meyzieu (France) - COFRAC Tests accreditation

no. 1-2000

and has been granted approval by the French Ministry of Ecology, Sustainable Development and Energy.

Our services

Testing of atmospheric waste emissions

Manumesure works on site to perform regulatory testing of atmospheric waste emissions, with COFRAC Tests accreditation.

- Measurement of speed and temperature (ISO 10 780)

- Measurement of humidity (NF EN 14 790)

- Continuous gas measurement: O2, CO2, CO, NOx, COV, CH4

- Measurement of dust (NF 44 052/EN 13-284), PM10 & PM 2.5 (ISO 23 210), particle-size analysis

- Measurement of metals, HF, HCl, SO2, NH3, N2O, acidity & alkalinity

- Measurement of dioxins and furans (PCDD/PCDF) (EN 1948-1)

- Measurement of polycyclic aromatic hydrocarbons (PAHs) (NF 43-329)

- Specific molecules on request (benzene, tar, specific VOCs, etc.)

Verification of automatic measurement systems

The regulations on waste incineration and major combustion installations oblige operators to check their continuous measurement equipment, used for automatic monitoring of atmospheric emissions.

MANUMESURE verifies the Automatic Measuring Systems (AMS) installed on industrial stacks in compliance with the QAL 2 and AST procedures, with COFRAC Tests accreditation.

QAL 2: Installation Quality Assurance

Verification of the automatic measuring systems by measurements in parallel with Standardized Reference Methods. The QAL2 procedure must be performed every 3 years. MANUMESURE works on site for 4 days. The first day is dedicated to the operational tests. During the 3 days that follow, several series of measurements are performed in parallel on the analyser. At least 15 measurements must be made. At the end of the operation, a series of statistical analyses is used to establish the calibration function for the AMS and define whether the analyser is capable of meeting the requirements in terms of measurements and uncertainties.

AST: Annual Surveillance Test

The AST procedure is performed once a year (when there is no QAL 2). Its aim is to check that the calibration functions defined during QAL 2 for the automatic measuring system (AMS) are still valid. The work is carried out over 2 consecutive days. On the first day, operational tests are performed, followed by at least 5 parallel measurements on the analyser.

Measurement of diffuse emissions

MANUMESURE measures diffuse emissions by implementing various sampling techniques.

MANUMESURE measures diffuse emissions by implementing various sampling techniques.

- measurement of dust and metal concentrations

- measurement of dioxin / furan concentrations

- measurement of benzene, formaldehyde, etc.

- specific measurements on request

Measurement of ambient air quality in public buildings

The French decree 2011-1728 of 2nd December 2011 concerning indoor air quality monitoring in certain public buildings stipulates that such monitoring will be implemented in stages, with four deadlines.

- Before 1st January 2015 for buildings providing collective child care (around 9,000) and infant schools (around 17,000)

- Before 1st January 2018 for primary schools (around 38,000)

- Before 1st January 2020 for outside-school leisure centres (33,000) and secondary education and professional training establishments (around 17,000)

- Before 1st January 2023 for other public buildings

MANUMESURE has developed expertise in ambient air measurement to meet the requirements of these new regulations and assist you with:

- assessment of ventilation systems

- definition of sampling strategies

- two measurement campaigns annually: 1 campaign when the heating systems are operating, with measurement of CO2, benzene and formaldehyde & 1 campaign when the heating systems are shut down, with measurement of benzene and formaldehyde

Fleet of mobile laboratories

MANUMESURE is equipped with a fleet of mobile laboratories enabling it to work on its customers' sites in France and in neighbouring countries.

MANUMESURE is equipped with a fleet of mobile laboratories enabling it to work on its customers' sites in France and in neighbouring countries.

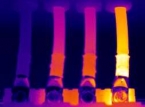

Infrared thermography

Manumesure performs safety inspections using infrared thermography.

Our expertise

MANUMESURE's operators are certified by the CNPP (French national centre for prevention and protection), as per APSAD* reference document D19, for the inspection of electrical installations by infrared thermography.

(*) French plenary assembly of damage insurance companies

Purpose of inspections using infrared thermography

Infrared thermography is a no-contact inspection technique used in a wide variety of sectors: electricity, mechanics, metallurgy, construction, etc.

This technique is used for preventive maintenance, as well as in production and R&D.

Applications in the electrical sector: viewing load unbalances, searching for abnormal hot spots, detecting bad connections in electrical cabinets which may cause a fire or service interruption, etc.

Methodology

The electrical installation inspections performed by MANUMESURE operators comply with technical document D19 published by the CNPP ( French national centre for prevention and protection)

This service is finalized by a Q19 report and a document detailing corrective recommendations for the anomalies detected.

Electrical inspections

Manumesure performs periodic verification of electrical installations and equipment.

Our expertise

Manumesure is COFRAC-accredited for "Inspection" of permanent electrical installations in workplaces.

Accreditation no. 3-145

Scope available at www.cofrac.fr

Manumesure also has "Insurance" approval from the CNPP (French national centre for prevention and protection) as per reference document Y18.

Approval no. 146/18.

This "verification of electrical installations with regard to fire hazards" is finalized by a Q18 report.

Objective of electrical inspections

The purpose of these periodic regulatory* verifications is to provide information on the ongoing safety level of electrical equipment or installations in order to protect people against the hazards of electric currents.

* French decree no. 2010-1016 of 30/08/2010, completed by the order dated 26/11/2011.

Methodology

Examination of the documents

Checking of the technical file which should contain the plans of the premises, the single-line diagrams of the installation, the list of the safety installations, etc.

Verifications

Specifications of the existing installations, general conditions of use, suitability of the equipment, identification of the circuits, etc.

Protection against risks of direct contact, insulation, separation, etc.

Protection against risks of indirect contact

Protection against burns, fire hazards and explosion.

Tests

Correct operation of emergency cut-off devices, safety lighting or RCDs (residual current devices).

Measurements

Insulation of the installations, earth electrode and equipotential bonding.

Calibration in COFRAC-accredited laboratories

Manumesure benefits from laboratories with COFRAC accreditation for "Calibration"

The scopes of our 8 accreditations are available at www.cofrac.fr

All our measurements have guaranteed traceability to the national standards.

Quantities measured with COFRAC accreditation in our laboratories

Electricity & Magnetism

MANUMESURE laboratory at Pont-l’Evêque (France)

COFRAC accreditation for "Calibration" no. 2-1035

MANUMESURE laboratory at Annecy (France)

COFRAC accreditation for "Calibration" no. 2-1405

Voltage, Current, Resistance, Capacitance, Power & Energy

DC voltage: 1 μV to 30 kV

AC voltage: 1 mV to 15 kV

DC current: 1 μA to 1,000 A

AC current: 10 μA to 1,500 A

DC resistance: 10 μΩ to 1 TΩ

AC resistance: 0.1 Ω to 10 kΩ

Capacitance: 1 pF to 1 μF

Single and three-phase power: 100 mA to 10 A at 57.7 V - 100 V - 230 V

Single and three-phase energy: 100 mA to 10 A at 57.7 V - 100 V - 230 V

Time & Frequency

MANUMESURE laboratory at Annecy (France)

COFRAC accreditation for "Calibration" no. 2-1406

New COFRAC accreditation for Calibration of centrifuges: rotation speed & time

Frequency, Time & Rotation Speed

Frequency: 1 mHz to 26.5 GHz

Time: 1 μs to 1,000 s

Rotation speed: 6 to 60,000 RPM

Temperature

MANUMESURE laboratory at Pont-l’Evêque (France)

COFRAC accreditation for "Calibration" no. 2-1336

PYROCONTROLE laboratory at Lyon (France)

COFRAC accreditation for "Calibration" no. 2-1385

MANUMESURE also performs on-site calibration of Pt 100 temperature sensors, from - 25 °C to + 150 °C

Platinum Resistance & Thermocouple

Platinum resistance: - 80 °C to + 500 °C

Thermocouple: - 80 °C to + 1,500 °C

Relative gas pressure

Relative gas pressure: 0 to 2.5 MPa

Micropipettes

MANUMESURE laboratory at Lyon (France)

COFRAC accreditation for "Calibration" no. 2-1913

Volume of micropipettes

Volume: 2.5 μl to 10 ml

Dimensions

MANUMESURE laboratory at Pont-l’Evêque (France)

COFRAC accreditation for "Calibration" no. 2-1310

The Pont l’Evêque laboratory is also equipped with a three-dimensional machine for checking parts on the basis of drawings.

Lengths, diameters & threads

Gauge block L: 0.5 to 500 mm

Gauge rod L: 0.1 to 20 mm

Plug gauge Ø: 20 to 200 mm

Thread plug gauge Ø: 1.6 to 100 mm

Plain ring gauge Ø: 2 to 200 mm

Vernier calliper L: 0 to 1,000 mm

Depth slide gauge L: 0 to 600 mm

Outside screw micrometer L: 0 to 200 mm

Mechanical comparator L: 0 to 30 mm

Spindle L: 25 to 600 mm

Electronic comparator L: 0 to 100 mm

Calibration & Verification

It the laboratory or on site, in France and internationally.

Manumesure offers a unique partnership to verify and calibrate your fleet of measuring instruments.

These services are proviced in our technical centres or on your site.

Two types of documents are issued, depending on your requirements:

- "FDX 07.011" verification certificate

- "FDX 07.012" calibration certificate

All our measurements have guaranteed metrological traceability to the national standards. These metrological verifications and calibrations can be performed for a large number of different measurement quantities.

The instrument families covered are listed below:

- Electricity: multimeters, megohmmeters, calibrators, loggers, wattmeters, power supplies, current clamps, etc.

- Low frequency: oscilloscopes, frequency meters, meters, function generators, fieldmeters, spectrum analysers, wattmeters, etc.

- High frequency: spectrum analysers, probes, amplifiers, attenuators, loads, radio test benches, filters, SWR meters, scalar analysers, frequency meters, wattmeters, etc.

- Telecom & IT: LAN testers (categories 4, 5, 6 and 6A), ADSL testers…

- Climatics: thermometers, hygrometers, anemometers, calibrators, Pitot tubes, gas flowmeters, collection systems, leak detectors, combustion analysers, etc.

- Dimensions: shims, pins, vernier callipers, micrometers, vee blocks, measuring columns, comparators, 3D systems, gauges, etc.

- Force: force sensors, torque wrenches, crimping tools, etc.

- Weighing: weighing machines, weights, etc.

- Pressure: manometers, pressure sensors, calibrators, etc.

- Physics & chemistry: pH-meters, conductivity meters, luxmeters, pyranometers, tachometers, etc.

Environment

MANUMESURE, the specialist in air, noise and water measurements

Watch the video (in French)

Summary of our services

Our expertise

MANUMESURE offers its know-how to quantify industries' impact on the environment.

Controlling their environmental impacts has become a major issue for industrial companies in order to reduce their ecological footprint, their energy consumption and their consumption of raw materials, while also improving their competitiveness.

MANUMESURE has been developing its expertise in environmental measurements concerning air, noise and water (waste water, rain water and underground water) for nearly 25 years.

Measurement of air quality

MANUMESURE works on site to test atmospheric emissions, with COFRAC Tests accreditation.

- Measurement of gases: O2, CO2, CO, NOx, COV, CH4, etc.

- Measurement of dust, PM10 & PM 2.5, etc.

- Measurement of metals, HF, HCl, SO, NH3, N2O, etc.

- Measurement of PCDD & PCDF, PAHs, etc.

MANUMESURE also provides verification of the "QAL2 and AST" measurement lines with COFRAC Tests accreditation.

In addition, MANUMESURE performs measurements of diffuse atmospheric deposition around sites.

Dust, dioxin, VOCs, benzene or any other molecule on request.

Measurement of noise levels

Manumesure performs regulatory noise-level testing on environmentally-sensitive installations.

The impact of the noise generated by an industry may disturb the neighbourhood and lead to conflict. Noise-level assessment is a regulatory requirement for environmentally-sensitive installations in France and in many other countries.

The regulations impose measurements at the property lines of sites and in regulated emergence zones (near housing).

Measurement of water quality

MANUMESURE performs on-site sampling in order to analyse water quality (waste water, rain water and underground water).

Water is an essential natural resource for living creatures and for human and economic activities, so it must be protected.

The regulations oblige industrial companies to monitor the quality of their water.